Shiga Plant

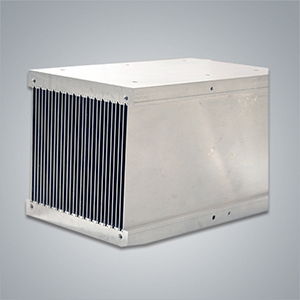

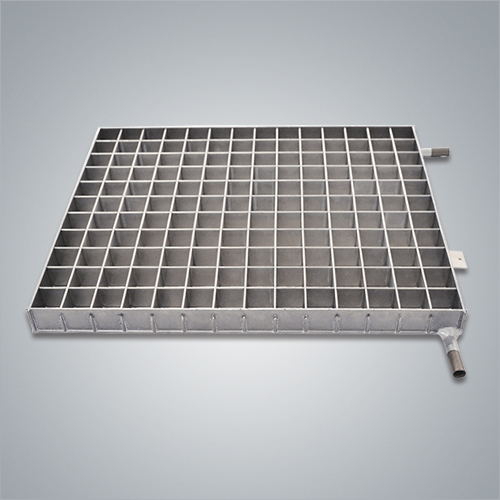

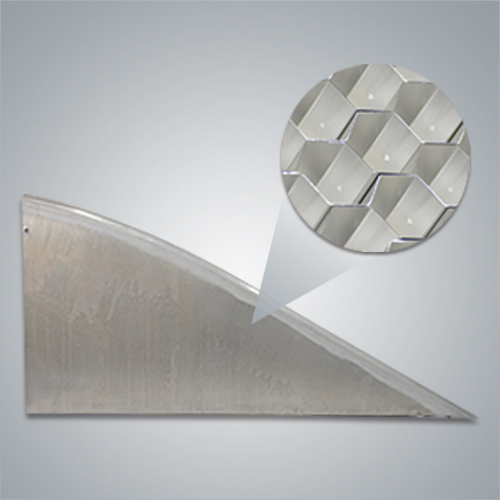

| Products/Services | Welded products, heat exchangers, craft and temple supplies, etc. |

|---|---|

| Site area | 55,080m2 |

| Number of employees | Approximately 130 |

| Location | 1 Kosuna-cho, Konan Shi, Shiga 520-3212, Japan |

| TEL | 0748-75-1161 |

| Certification |

|

This was the first plant in Japan to be certified as a light metal welded structure manufacturing plant. The plant has received high praise for its top-class welding technology and produces everything from industrial products to craft items.