Ena Plant

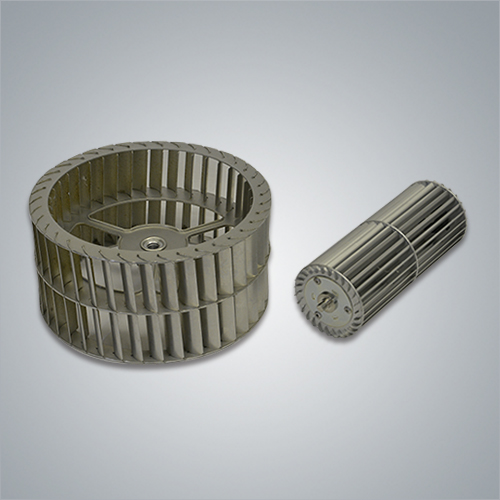

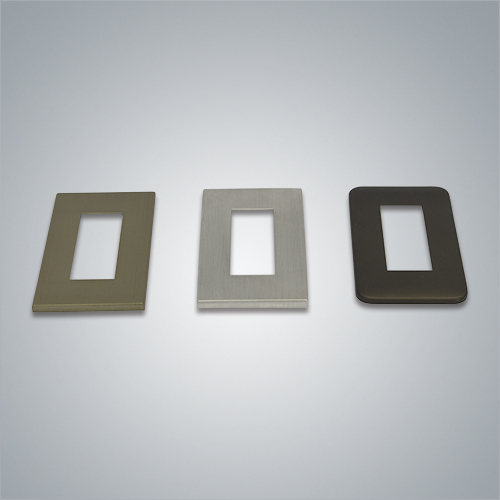

| Products/Services | Aluminum press-worked products. Anodizing and metal bat manufacturing |

|---|---|

| Site area | 20,500m2 |

| Number of employees | Approximately 100 |

| Location | 18-1 Kusumi, Osashima-cho, Ena Shi, Gifu 509-7206, Japan |

| TEL | 0573-27-3111 |

| Certification |

|

We aim to achieve diverse, high-quality manufacturing from mold design to processed products in both small and large lots.