Narita Plant

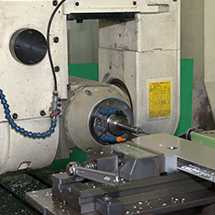

| Products/Services | Unit bath panels, parts for vehicles and rolling stock, railing for construction, etc. |

|---|---|

| Site area | 21,170m2 |

| Number of employees | Approximately 140 |

| Location | 11-2 Shinizumi, Narita Shi, Chiba 286-0825, Japan |

| TEL | 0476-36-1155 |

| Certification |

|

We have a wide range of processing technologies for industrial equipment and railing-related items, including unit bath panels, vehicle components, and railing.