Sendai Plant

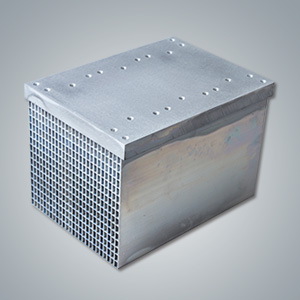

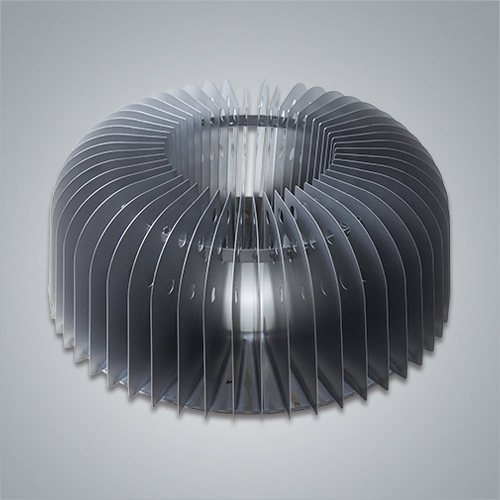

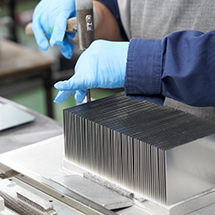

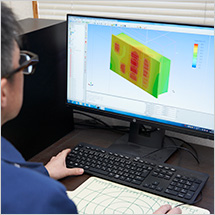

| Products/Services | Large and small heat sinks and automotive parts |

|---|---|

| Site area | 31,316m2 |

| Number of employees | Approximately 80 |

| Location | 11-1 Myojindo, Kaminomyo, Shibata-machi, Shibata-gun Sendai, Miyagi 989-1611, Japan |

| TEL | 0224-55-1441 |

| Certification |

|

We supply products to major heavy electric companies.

We provide custom-made products that meet the specifications of our customers in both small and large quantities.